Immediately after its appearance, plastic bottles gained huge popularity among beverage and food manufacturers, due to their low cost, lightweight and wide possibilities of color design, flexibility. Currently, plastic bottles have confidently displaced glass and tin containers from the food market, due to the low cost of production, as well as the possibilities of recycling.

Our company presents a wide range of preforms for plastic bottles, which serve as the basis for the manufacture of durable and lightweight containers.

For the manufacture of preforms for bottles, we use the material polyethylene terephthalate, which becomes plastic when heated, so that by blowing out PET preforms, we receive capacious bottles with the same wall thickness and high strength.

The immunity of plastic to the impact of acids, alkalis, chemically active substances and bacterial cultures opens up wide prospects for using preforms for the manufacture of containers for car oils, alcoholic, carbonated drinks and juices, cleaning supplies, etc. Plastic also demonstrates high hygienic properties.

- Non-alcoholic and beer production

- Agricultural enterprise

- Restaurants Bavaria

- Mountain spring water «TBAU»

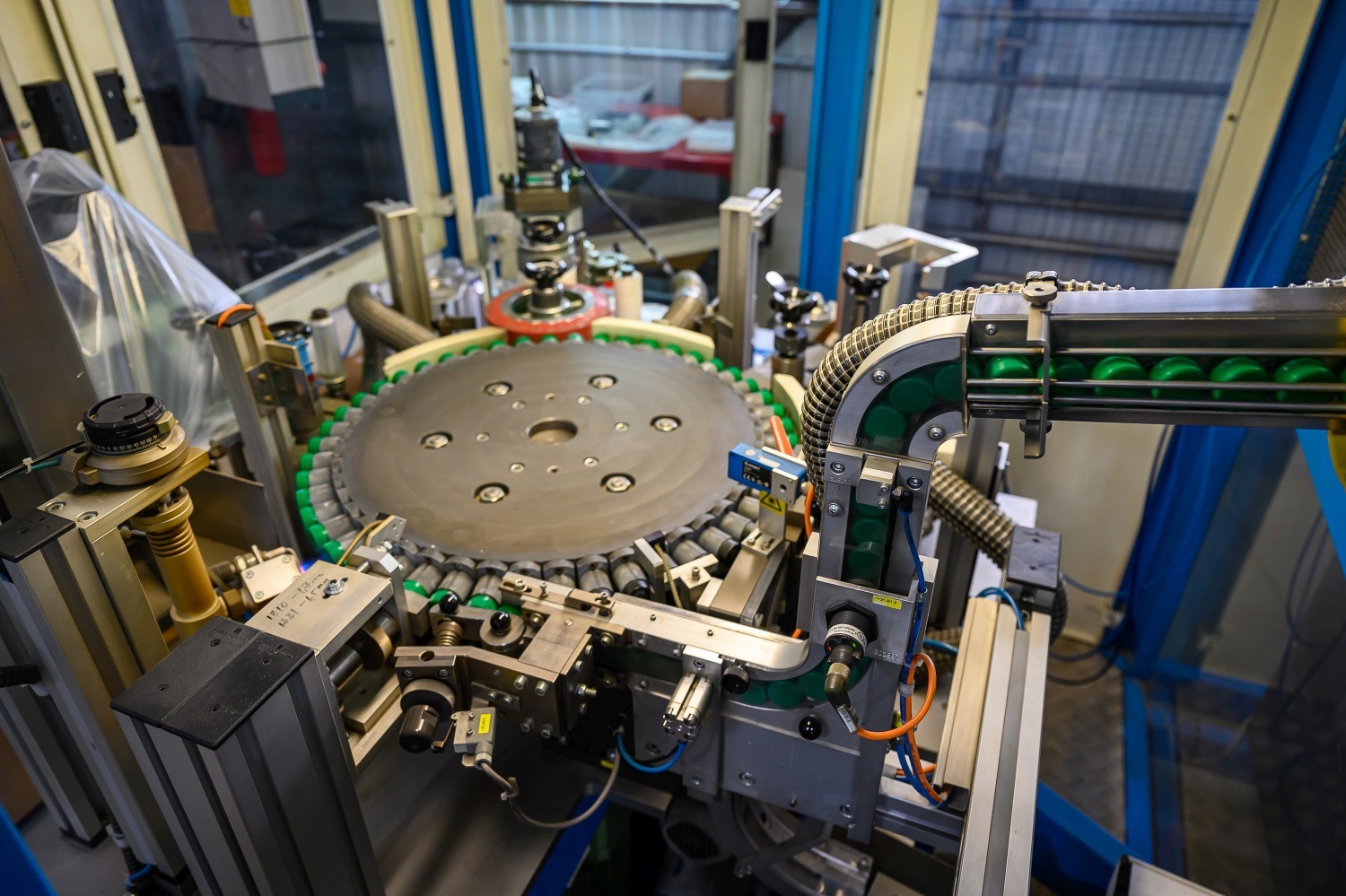

- Production of pet preforms and caps

- Media Center «15 Region»

- Витаминные напитки Rocket Ride

- Craft brewery «The Black Satellite»

- Tank Beer

- Concrete and mortar department

- Corporate University

- Catering

- Brand minimarkets «BEERÆ»

- Sausage manufactory

- Confectionery manufactory

- Bakery production

- Alpina Family Park

- New Jersey Cafe

- Velvet Restaurant

- Animals Cafe

- Bruges Restaurant

- Торговый центр «Галерея»